Gréement courant

Une gamme étendue de cordages de haute qualité et de haute performance pour les voiliers. Nous avons des cordages spécialisés pour les écoutes, les drisses, les bouts de réglage, les amarres pour les voiliers de croisière et de course. En savoir plus...

Choosing the right ropes for your boat and each specific application is paramount to ensure safety, reliability, and performance on the water. Below we explore the best materials for modern boat ropes, different rope constructions available, and which type of rope to use in different applications.

What are the Best Materials for Modern Boat Ropes?

Nylon ropes are popular choices for boat applications due to their excellent strength, elasticity, and resistance to UV degradation and abrasion. They are relatively affordable and offer reliable performance in various conditions.

Polypropylene ropes are lightweight, buoyant, and resistant to water absorption, making them suitable for applications where floatability is crucial, such as tow lines and floating dock lines.

Polyester ropes are known for their low stretch, high strength, and resistance to sunlight and chemicals. This boat ropes are ideal for applications where minimal elongation and durability are essential, such as halyards and control lines. The vast majority of braided covers are made primarily from Polyester, due to its abrasion resistance and excellent grip for cruising boat and club racers up to 45ft polyester rope swould be the default starting point.

Dyneema ropes, crafted from ultra-high molecular weight polyethylene (UHMWP) fibers, offer exceptional strength-to-weight ratio, minimal stretch, and resistance to abrasion. This boat ropes are preferred for performance sailing applications for boats under 45ft and both cruising and racing yachts abive 45ft. They provid lightweight and reliable performance. There are two primary grades of Dyneema® used on modern ropes. SK78 has taken over as the primary standard material (superceeding the use of SK75 in all but a few cases), whilst SK99 is used in high performance applications where minimum stretch is required.

Braided Cover fibres – The primary material for cover braids is Polyester, due to its excellent handling, durability and abrasion resistance. However, many different more exotive fibers can be blended with the polyester to improve pwrformance of the cover in various applications. For example, Technora® and Cordura® are often used to improve abrasion resistance and improve grip in clutches. Kevlar and Vectran can be incorporated into the cover to improve heat resistance and PBO (Zylon®) to increase overall rope strength.

What Different Boat Rope Constructions are There?

Twisted Ropes:

Twisted ropes are created by twisting individual strands of fiber together to form a rope. They are traditional and economical options, offering good strength and durability for general-purpose use on boats. Main applications will be mooring lines, fender lines, lazy-jacks and some other non-performance critical applications.

Singe Braid Ropes:

Single braided ropes are constructed by braiding multiple strands of a core fiber together to form a strong and flexible rope. They have no braided cover and therefore, for their diameter, they have higher break-strength and lower stretch than a double braid rope (see below), and they are very quick and easy to slice. They are versatile and offer excellent handling characteristics, making them suitable for a wide range of applications where there is high load and low movement e.g. jib halyards, purchase systems or some control lines.

Double Braid Ropes:

Double braid ropes consist of a braided core surrounded by a braided outer cover, providing enhanced strength, durability, and abrasion resistance. They are the default solution for high-load applications such as halyards and sheets on sailboats. For boats up to 45 ft the starting point would be a double braid Polyester i.e. with a Polyester core and 100% polyester cover. However for bigger boats and for more performance the core can be upgraded to SK78 Dyneema and the polyester cover can be supplemented with other fibres to improve grip, abrasion resistance and even heat resistance, depending on application.

Can I Use the Same Rope for Both my Yacht’s Sheets and Halyards?

Considerations when using the same boat rope for Multiple Applications:

1. Compatibility: While it is possible to use the same rope for both sheets and halyards on your yacht, it's essential to ensure that the rope's characteristics meet the requirements of both applications. Consider factors such as strength, stretch, and handling characteristics to determine suitability.

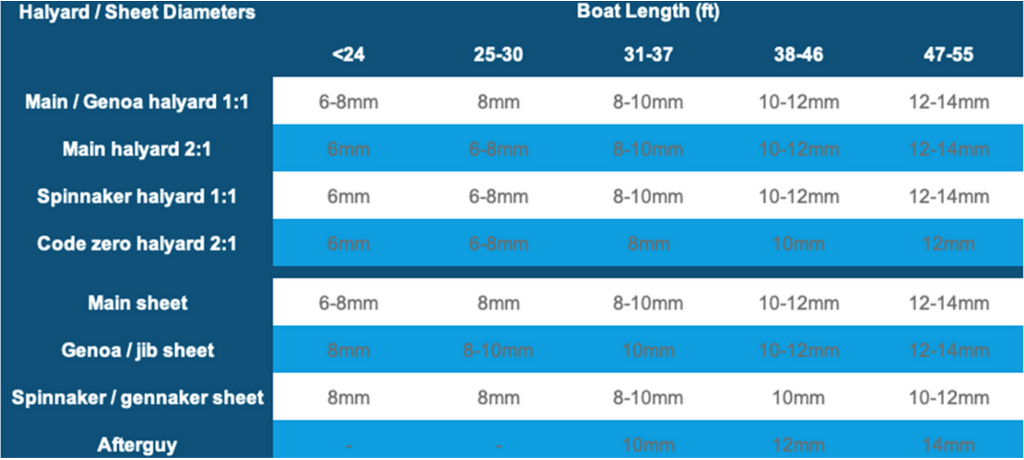

2. Load Requirements: Sheets and halyards experience different loads and tensions during use. Ensure that the selected rope has the necessary strength and low stretch properties to handle the specific loads encountered in each application. The strength and stiffness of a rope will be determined by what core material is used and then increasing diameter increases strength. The table below provides a rough guide for the correct diameter for sheets and halyards on a mid-displacement monohull:

3. Handling: Sheets and halyards require different handling characteristics due to their distinct functions. Choose a rope that offers the desired grip, flexibility, and ease of handling based on the application requirements.

4. Durability: Both sheets and halyards are subjected to wear and tear from constant use and exposure to the marine environment. Select a rope with sufficient abrasion resistance and UV stability to ensure long-term durability in both applications.

In conclusion, boat ropes are essential components of any vessel, offering crucial functions from sail control to anchoring and towing. By understanding the best materials for modern boat ropes, different rope constructions available, and the versatility of using the same rope for multiple applications, boat owners can make informed decisions to enhance safety, reliability, and performance on the water. Whether it's nylon, polyester, Dyneema®, or polypropylene, selecting the right rope for your boat ensures smooth sailing and enjoyable experiences on the water.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.