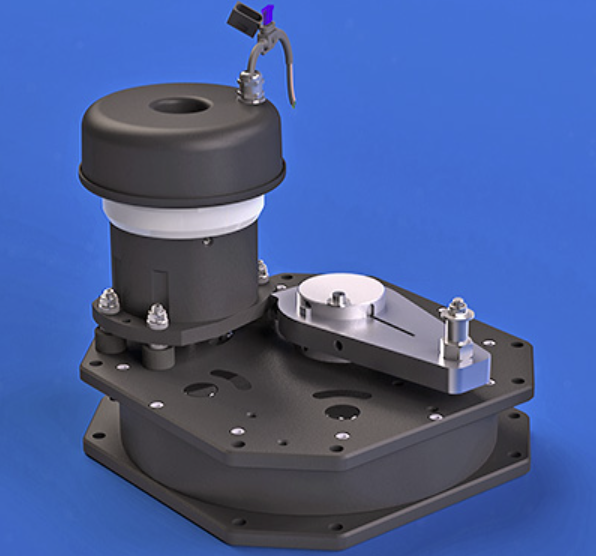

Jefa Steering Autopilot Direct Drive - DD2, 375 KgM

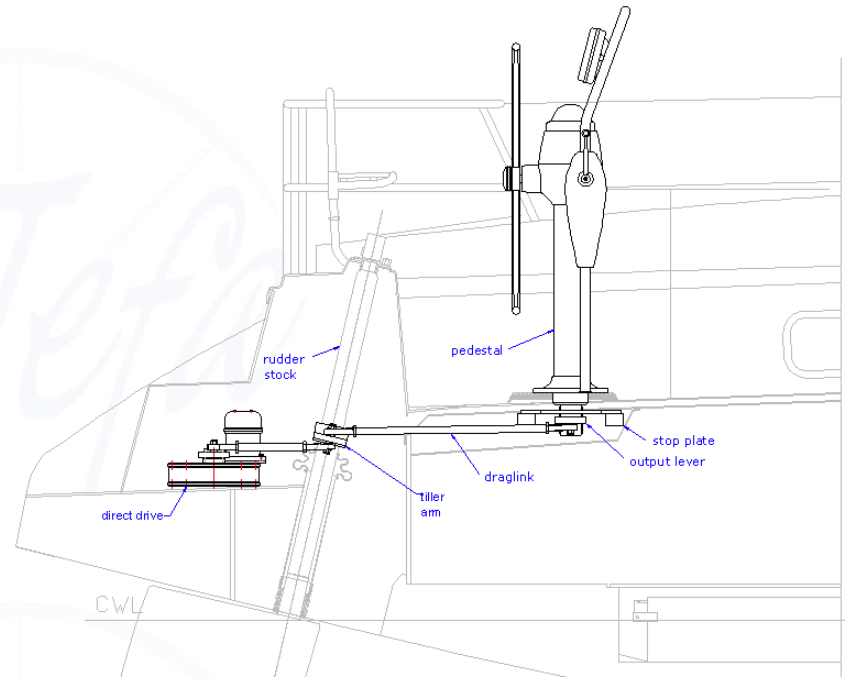

The Jefa Direct Drives are extremely robust, compact units with simple installation. The big advantage of the Jefa Direct Drives is that the rudder feedback arm is mounted on the Drive itself which saves a considerable amount of installation and system tuning time. The 375 KgM output torque is good for boats from 40 feet up to 55 feet.

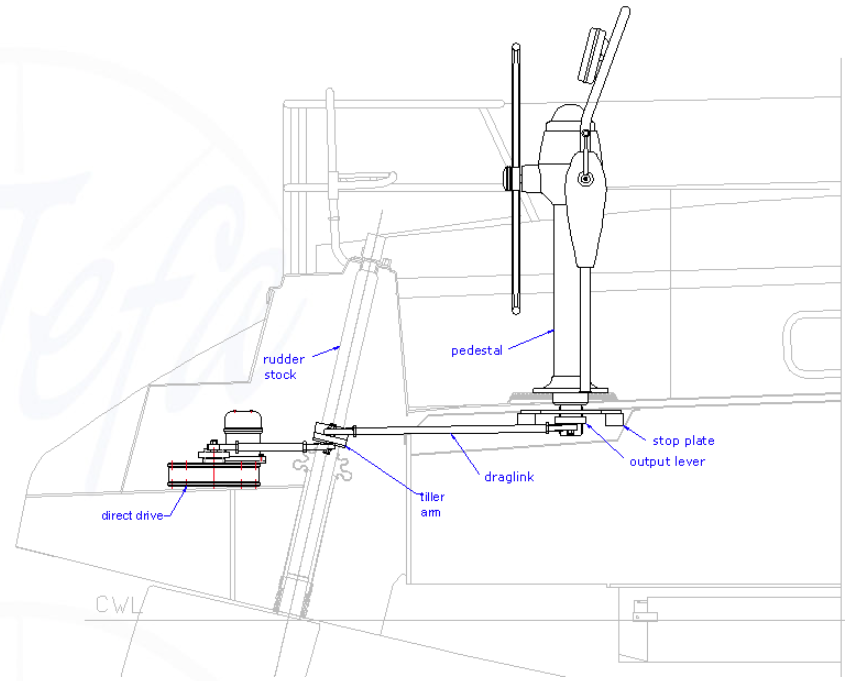

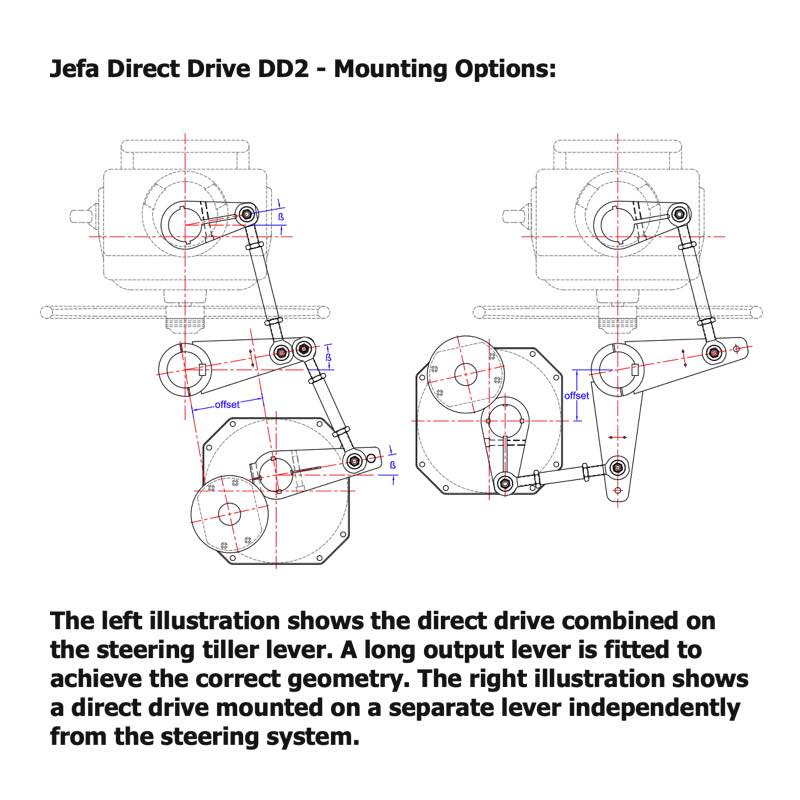

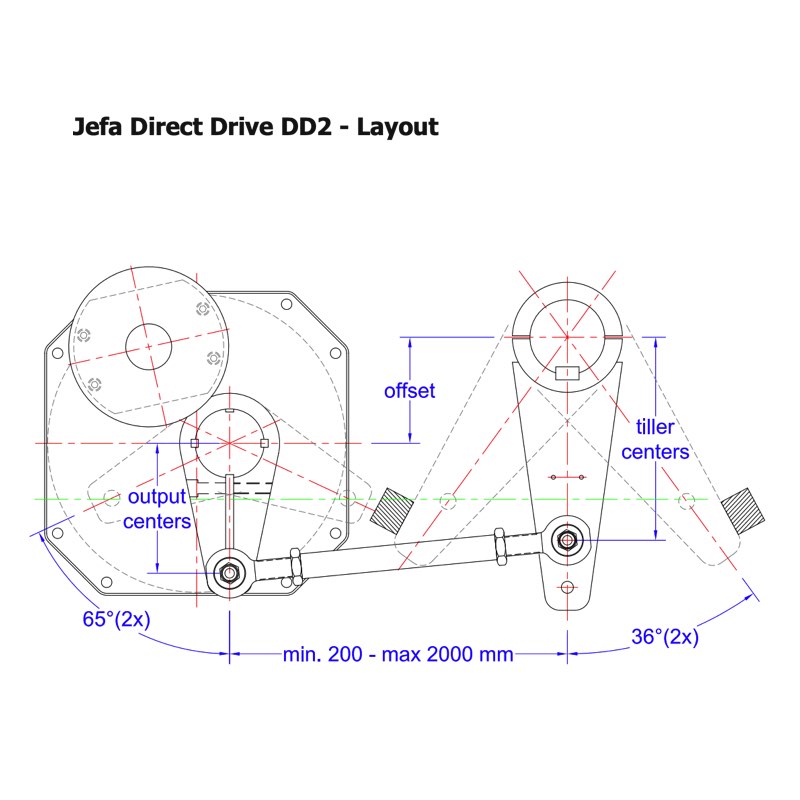

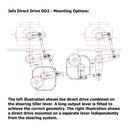

The Direct Drive controls the rudder using a drag link which can be used directly on the existing tiller arm, via the quadrant or and independent tiller arm. The unit can be mounted in any orientation, even upside down. These units are built for 24hr continuous operation and have a total weight of 19kg

Available in 12V and 24V. Quotes for 24V system available on request.

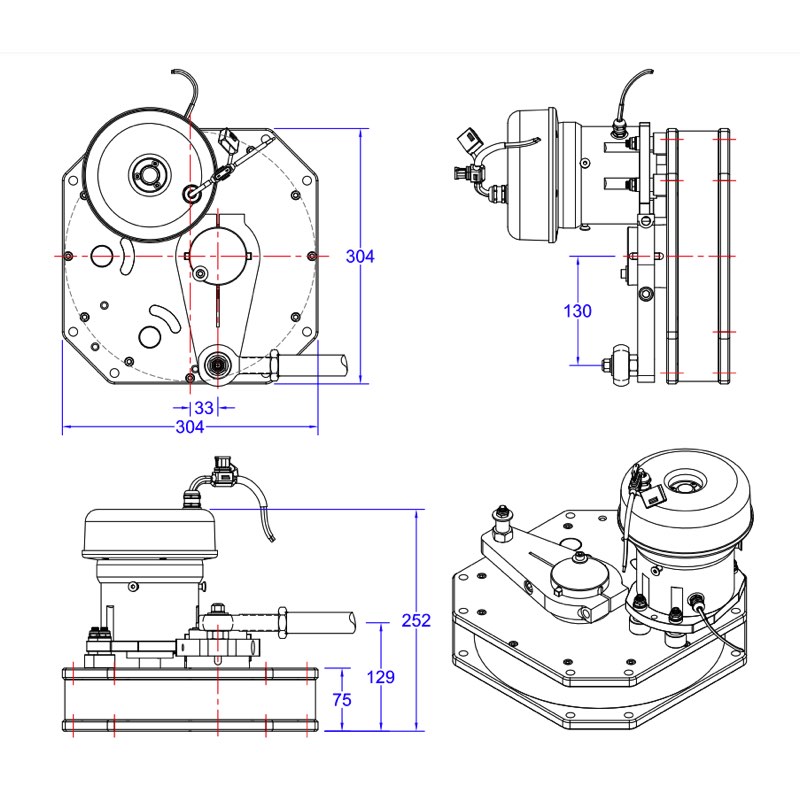

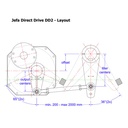

Main dimensions:

The Jefa 375 KgM direct drive is very compact with a length of 304 mm, a width of 304 mm and a height of 252 mm. As space is always a problem on sailing yachts, the direct drive unit can be mounted as close as 250 mm from the rudderstock even upside down. The standard version has an output lever centre of 130 mm to work with 200 mm tiller centres. A long version of the output lever is available to work with 2500 and 307 mm centres (please specify on order).

The construction:

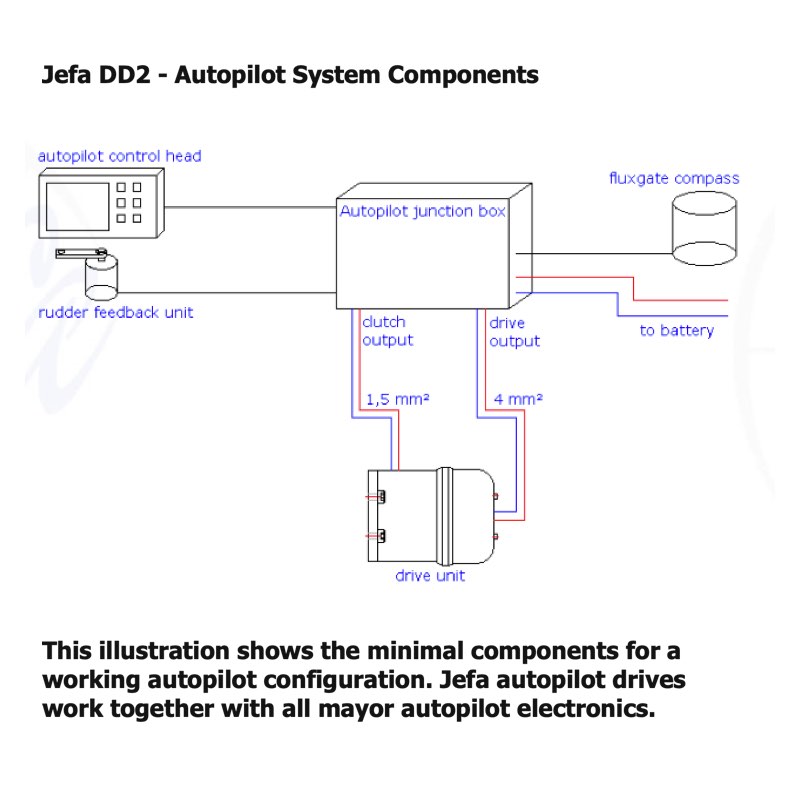

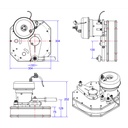

The drive can be separated in 4 main parts: The electric motor (1), the three stage planetary gearbox (2) and the electro-magnetic clutch (3) and the 1:5 spur reduction gearbox (4). The Jefa direct drive has multiple advantages over existing integrated drive units. These advantages will be explained per section of the drive:

Electric Motor: The flat wound electric motor used in the Jefa drive units is not a standard industrial motor, but specially designed and produced for this application. This solution is more expensive but there are multiple advantages over standard industrial motors.

- The collector (1) is extremely big so a large contact surface of the coal brushes is achieved. The result of this is a very high efficiency under heavy load and a very small drop in speed at the maximum torque.

- The central motor shaft runs in ball bearings in stead of gliding bearings. This results in a higher efficiency, less noise and a much longer life time.

- A large flat wound rotor to achieve a high starting toque and an immediate response to the autopilot speed control signal.

- Specially produced magnets with an extremely long lifetime and field strength. (Normal magnets can loose up to 50% field strength over a couple of years).

- Aluminium motor housing in stead of sheet steel plate to avoid corrosion.

Planetary gearbox: To achieve a correct rudder travel speed (hard over time) the electric motor has to be reduced in speed with a factor 486:1. Some autopilot drive producers use a worm reduction box, but the efficiency is extremely low as the gears rub each other. Some producers use a combination of a planetary gearbox with a 2 stage spur gear set (one small gear and one big gear), but this creates a much bigger unit with an offset to the centre and much heavier loaded gears. The best way to achieve this high reduction in combination with a high torque is a 3 stage planetary gearbox. It's also the most expensive way as every gear step has 4 gears in stead of 2 gears but the huge advantages overrule the higher price:

- The highest possible efficiency compared to any other gearbox.

- All forces are equally spread over 3 gear teeth in stead of one allowing a much compacter and stronger solution.

- The forces and torques from the motor to the output shaft remain in the centre line of the drive unit, resulting in a higher efficiency and extremely reduces the loads on the housing and other internal parts.

Electro magnetic clutch: On the moment the mechanical steering system on the yacht is manually operated, the autopilot drive has to be disconnected from the steering system. This is achieved with the electro-magnetic clutch (4) and controlled automatically by the autopilot junction box. Jefa has developed a unique and patented engagement clutch. The solution is based on two electrically operated spring loaded clutch pins that engage and disengage the outer gear ring of last planetary gear step. This solution has multiple advantages over the existing friction plate clutches:

- Less friction to back drive the unit.

- Lower power consumption (1.4 Amp. at 12 Volt, 0.7 Amp at 24 Volt). When the clutch isn't powered, it's disengaged and engaged when powered.

- The clutch doesn't wear in time.

- More compact than any friction clutch.

- When the autopilot is switched off, the helmsman isn't suddenly confronted with the full rudder torque, but has to put loading on the wheel to equalise the forces so the the clutch can disengage, making the manual take over much safer.

Spécifications

| Taille bâteau recommandée - Max (ft) | 55 |

| Taille bâteau recommandée - Min (ft) | 40 |

| Tension de fonctionnement | 12 |

| Couple max (kgM) | 375 |

| Consommation (mA) | 1400 |

| Garantie (année) | 2 |

| Poids (g) | 19000 |

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.